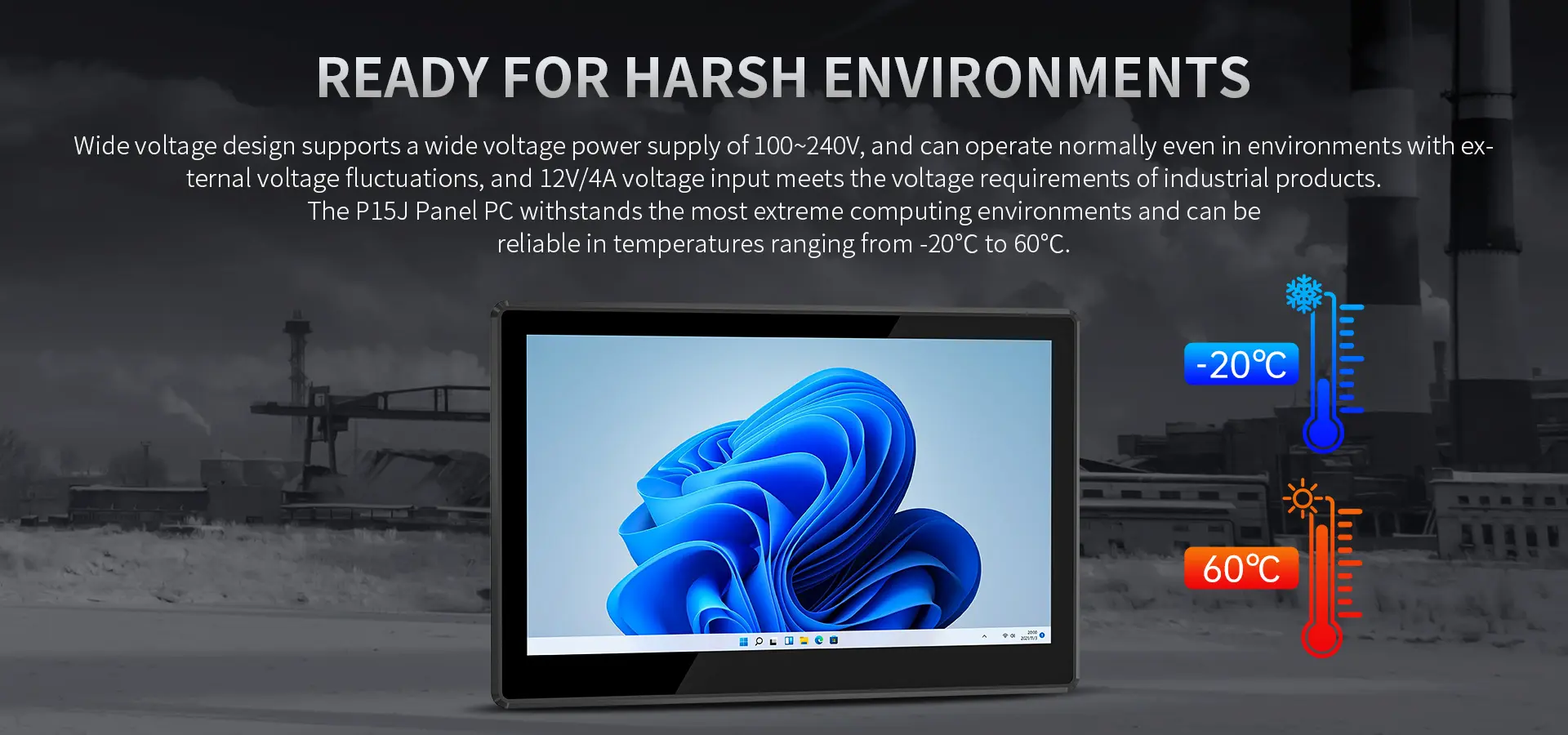

As modern industries accelerate toward digital transformation, the demand for computing systems capable of stable, uninterrupted performance has never been greater. From automated assembly lines and oilfield monitoring to heavy manufacturing and IoT-enabled smart operations, enterprises increasingly rely on industrial PC computers to run mission-critical tasks. Among the many performance indicators that define a high-quality industrial computing platform, one factor stands out as foundational—its ability to operate reliably within extreme temperature ranges, particularly -20°C to 60°C.

This temperature tolerance is not just a technical specification—it is a key enabler of operational continuity in environments where heat, cold, and thermal fluctuation would immediately disable consumer-grade hardware. This article provides an in-depth exploration of why industrial control all-in-one computers excel in harsh temperature environments, how they deliver long-term stability, and what makes them indispensable across various industrial application scenarios.

Industrial environments are rarely temperature-controlled. Outdoor installations face seasonal extremes, while indoor production lines may experience persistent high heat. These harsh conditions pose significant risks to ordinary computing devices—overheating, material fatigue, frozen components, and rapid degradation.

Industrial PC computers are equipped with high-reliability components that undergo strict quality screening and certification. Key features include:

High-temperature capacitors and chips that maintain electrical stability even under long-term thermal stress

Industrial-grade PCB materials designed to resist warping, expansion, and micro-crack formation

Solid-state storage that ensures stable read/write operations across wide temperature fluctuations

Rigid connectors and reinforced interfaces that prevent contact failure caused by contraction or expansion

These engineering details allow industrial PCs to maintain predictable performance where consumer devices commonly fail.

Heat management is critical to computing stability. Industrial control all-in-one computers integrate:

Fanless cooling structures that use passive heat dissipation fins, eliminating dust ingress and fan failure

Intelligent heat conduction architecture, ensuring even heat distribution throughout the system

Purpose-built ventilation pathways and thermal insulation layers to prevent component overheating

Low-temperature boot mechanisms, enabling stable startup under sub-zero conditions

This ensures industrial PCs can run continuously in environments where temperatures can swing drastically within minutes—such as oil rigs, metallurgical furnaces, or exposed outdoor facilities.

The ability to operate from -20°C to 60°C dramatically broadens the usage scenarios for industrial PC computers. Instead of being limited to climate-controlled facilities, these devices can be deployed in environments where extreme temperatures are the norm.

Oil and gas sites deal with harsh climates, from desert heat and direct sunlight to winter nights far below freezing. Industrial all-in-one PCs support:

Real-time equipment monitoring

Oil well data acquisition

Safety management and alarm systems

Integration with IoT edge devices

Their stability ensures that critical data remains accurate even when exposed to extreme environmental stress.

Steel plants and smelting facilities operate under constant high-temperature conditions. Industrial PC computers provide:

High-precision monitoring of thermal processes

Coordination of automated machinery

Data visualization for production control

Durable operation near furnaces, kilns, or molten metal zones

Their heat-resistant architecture ensures safe, uninterrupted industrial automation.

The rising adoption of Industrial IoT (IIoT) increases the demand for durable computing endpoints capable of real-time decision-making. In temperature-heavy automation environments, industrial PCs serve as:

Edge computing nodes

SCADA and MES terminals

Robotic control interfaces

Data processing hubs

Even during long production cycles, they maintain consistent performance regardless of environmental temperature shifts.

Harsh outdoor temperatures affect transportation hubs, logistics vehicles, mining sites, and railway operations. Industrial PC computers provide:

Vehicle dispatch coordination

Route planning and load monitoring

Environmental sensing and safety alerts

Stability under prolonged sun exposure or winter frost

Their ability to withstand thermal extremes ensures operational continuity across entire logistics chains.

One of the biggest advantages of industrial all-in-one PCs is their ability to maintain high computing power even under temperature stress.

These devices typically integrate:

High-performance industrial CPUs

Large-capacity RAM for multitasking

GPU acceleration for visualization and automation algorithms

Optimized industrial buses and communication protocols

Even when ambient temperatures approach operational limits, performance remains smooth—ensuring uninterrupted workflow execution.

Temperature does not affect:

Algorithmic processing

Machine vision analysis

Industrial protocol communication (Modbus, CAN, PROFIBUS)

Real-time sensor data collection

This makes industrial PCs essential for environments where real-time accuracy is non-negotiable.

Enterprises invest in industrial PCs not only for performance but for longevity. High-quality industrial devices deliver:

Long service life due to reinforced materials

Resistance to dust, vibration, and moisture common in harsh settings

Lower failure rates, reducing shutdowns and maintenance cycles

Lower total cost of ownership across long industrial deployment periods

Every structural detail—from internal architecture to external housing—is designed to ensure reliable operation despite years of exposure to extreme temperatures and heavy workloads.

The ability of industrial PC computers to maintain stable performance in temperatures ranging from -20°C to 60°C makes them indispensable across modern industrial sectors. Their advanced thermal engineering, robust architecture, high processing performance, and long-term durability equip them to handle some of the world’s harshest environments—whether it is freezing outdoor installations, high-heat industrial workshops, or temperature-fluctuating production lines.

As industries continue moving toward smart automation and IoT-driven operations, industrial all-in-one PCs will remain a core backbone of industrial digitalization—ensuring reliability, efficiency, and long-term value in every application scenario.

Industrial PC computers are engineered for harsh environments where dust, vibration, moisture, and extreme temperatures are common. Unlike consumer-grade devices, they use industrial-grade components, wide-temperature chips, long-life capacitors, and reinforced housings to ensure stable performance in demanding industrial applications such as automation, manufacturing, and IoT edge computing.

Many industrial environments—outdoor installations, factory floors, steel plants, cold chain logistics, oil exploration sites—experience temperatures far beyond standard office conditions. A wide operating temperature range ensures that the industrial computer can run continuously without overheating, freezing, or experiencing performance degradation, guaranteeing operational stability in mission-critical scenarios.

Yes. Industrial all-in-one computers are designed for uninterrupted 24/7 operation. Their fanless cooling structures, rugged components, and optimized heat dissipation systems allow them to handle high-intensity computing workloads and real-time automation processes while maintaining stable performance around the clock—even in temperature-heavy environments.

Wide-temperature industrial PCs are essential for industries such as:

Oil & Gas monitoring

Metallurgy and high-temperature manufacturing

Smart factories and industrial automation

Transportation, logistics, and warehouses

Mining and outdoor engineering

IoT edge computing environments

Any operation exposed to heat, cold, dust, or mechanical shock benefits significantly from rugged industrial computing solutions.

Industrial PCs incorporate advanced thermal designs including fanless cooling systems, heat dissipation fins, metal chassis conduction, industrial-grade CPUs, and optimized internal layouts that distribute heat evenly. These systems prevent overheating and ensure long-term reliability—even when ambient temperatures reach 60°C.