The customer is a container service company operating engineering vehicles in port container yards.

Previously used tablets suffered from poor visibility under direct sunlight, loose connectors caused by vehicle vibration, and incompatibility with high onboard voltage systems.

To support digital container yard operations, the customer urgently needed a vehicle-mounted tablet featuring sunlight-readable display, heat resistance, secure interfaces, wide-voltage input, and 4G connectivity.

In Onerugged Transformation Story – Episode 2, we explore how the Onerugged V10J vehicle-mounted rugged tablet supports and accelerates the digital transformation of container yard operations.

During daily port and yard operations, the customer faced multiple issues with traditional tablets:

In outdoor port environments, screens were difficult to read under direct sunlight, making it hard for operators to accurately view container IDs, task instructions, and positioning data.

Engineering vehicles generate constant vibration during operation, causing tablet connectors to loosen. This resulted in unstable power supply and signal transmission.

Different vehicles operate under varying voltage levels. Some models use higher voltage systems, which traditional tablets could not tolerate, leading to unexpected shutdowns or reboots.

In large container yards and ports, weak network stability caused frequent disconnections, preventing real-time data upload and affecting remote management and technical support efficiency.

The Onerugged V10J vehicle-mounted rugged tablet provides a robust, reliable, and intelligent in-vehicle display terminal for engineering vehicles, accelerating container yard digitalization.

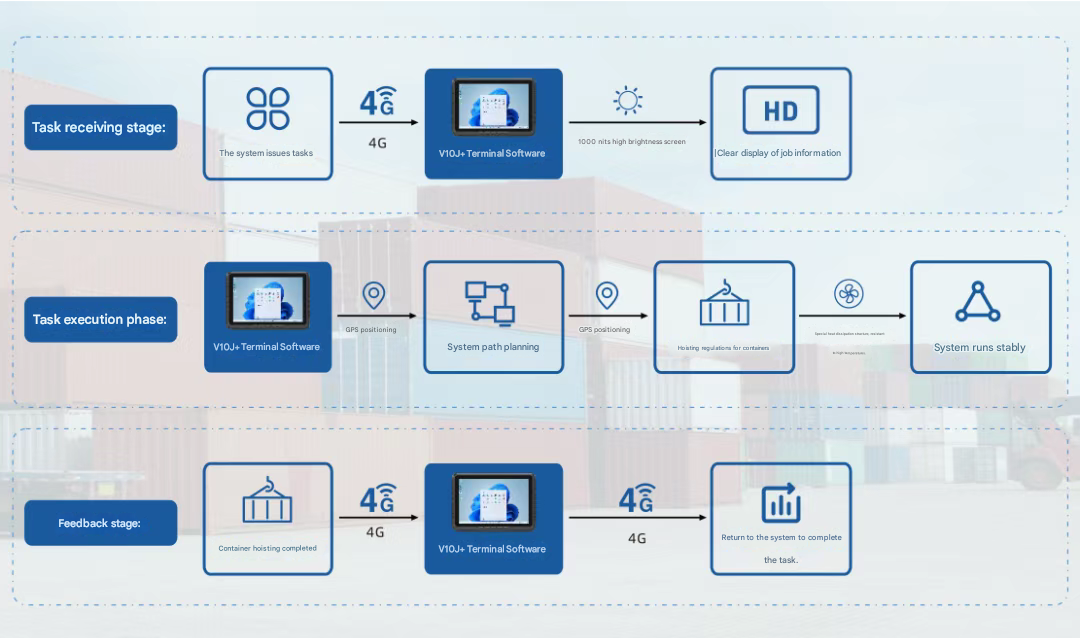

Once tasks are assigned by the dispatch center, the V10J receives instructions in real time via 4G connectivity. Its integrated GPS module allows dispatchers to monitor vehicle locations instantly, enabling precise route planning.

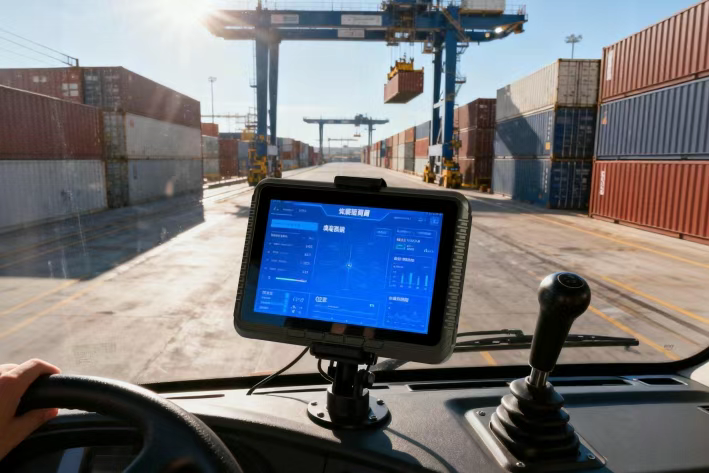

Following GPS navigation on the V10J, operators drive reach stackers to designated container positions. Thanks to its 1000-nit high-brightness display, container numbers, locations, and lifting instructions remain clearly visible even under intense sunlight.

Throughout extended shifts exceeding 8 hours, vehicles repeatedly start, stop, and vibrate. The V10J’s industrial-grade aviation connectors ensure secure cable connections, maintaining stable power and signal transmission.

Its wide-voltage design supporting up to 48V adapts to voltage fluctuations, while the large-area heat dissipation fins guarantee continuous high-performance operation in enclosed, high-temperature cabins—preventing system lag or crashes.

With brightness up to 1000 nits, the V10J ensures clear visibility under strong sunlight and maintains stable system performance inside hot crane cabins.

The aviation connectors are engineered to withstand long-term vehicle vibration, preventing loose connections and ensuring reliable power and data transmission.

Supporting 9–36V or 20–80V wide-voltage input, the V10J adapts to standard 24V and high-voltage 48V vehicles, avoiding failures caused by voltage fluctuations.

The built-in 4G module ensures continuous network access across large yards, enabling real-time vehicle data transmission and efficient remote management.

Integrated GPS enables accurate vehicle tracking, significantly improving dispatch efficiency and accelerating container turnover.

Intel® N5100 Processor

Windows 11 Operating System

10.1-inch High-Brightness Display

Wi-Fi / Bluetooth / 4G Connectivity

Multiple aviation connectors supporting USB / DB9 / LAN / CAN

IP65-rated dustproof and waterproof

Vibration resistance and wide temperature tolerance

“Even under the intense midday summer sun, the V10J displays information clearly. Its response speed exceeded expectations, remained stable in high temperatures, and all cables stayed securely connected—ensuring both efficiency and accuracy in our yard operations.”

— Container Yard Operations Supervisor

1. What is the Onerugged V10J used for in container yard operations?

The Onerugged V10J serves as a vehicle-mounted rugged display terminal for engineering vehicles, supporting task dispatching, navigation, real-time data display, and digital yard management.

2. Why is a sunlight-readable tablet important for port logistics?

Port and container yard environments operate under strong sunlight. A 1000-nit sunlight-readable display ensures operators can clearly view instructions, improving safety and efficiency.

3. How does the V10J handle vehicle vibration and harsh conditions?

The V10J uses industrial-grade aviation connectors, IP65 protection, and vibration-resistant design to maintain stable power and data transmission during continuous vehicle operation.

4. Does the V10J support wide voltage input for industrial vehicles?

Yes. The V10J supports 9–36V or 20–80V wide-voltage input, making it compatible with 24V and 48V engineering vehicles commonly used in container yards.

5. How does GPS and 4G improve container yard digitalization?

GPS enables real-time vehicle tracking, while 4G ensures stable data transmission—together improving dispatch efficiency, remote management, and overall yard productivity.