In the world of rugged computing, reliability is not just a feature—it is paramount. Professionals in industries like logistics, manufacturing, and field services rely on rugged laptops, rugged tablets, and industrial PCs to perform flawlessly despite accidental drops, impacts, rain, or extreme temperatures.

At ONErugged, we prioritize this critical need, investing heavily in research, development, and testing to deliver industry-leading devices that set the standard for durability. In the first episode of Extreme Testing Ground, we invite you inside ONErugged’s state-of-the-art reliability laboratory. Here, we explore the rigorous testing processes that ensure our products—from a rugged linux tablet to a high-performance rugged ultrabook—thrive in the toughest conditions.

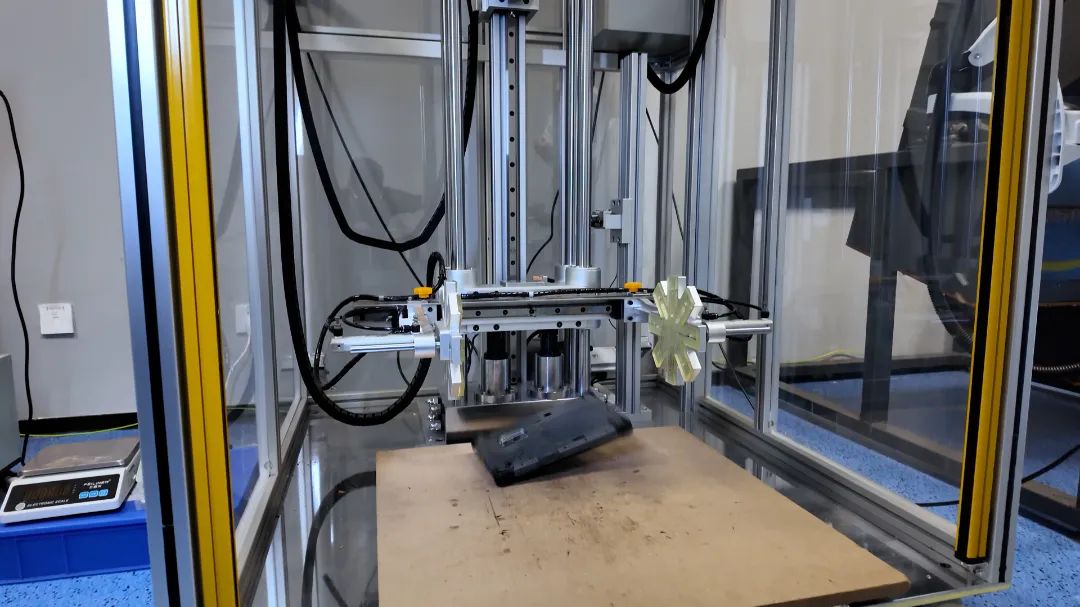

ONErugged’s commitment to excellence begins with our advanced, multi-million-dollar in-house laboratory. Equipped with cutting-edge testing equipment and staffed by expert technicians, our facility simulates real-world scenarios to validate the durability of our rugged computers.

From drops and vibrations to extreme environmental conditions, our tests are designed to push devices to their limits. This ensures they meet the demands of professionals, whether they are using an industrial android panel pc in a factory or a rugged pda in a warehouse. This episode focuses on our drop reliability laboratory, where we conduct exhaustive tests to achieve MIL-STD-810 certification, the global benchmark for rugged durability.

The MIL-STD-810 standard, originally developed for U.S. military equipment, is a comprehensive framework for assessing a product’s resilience in harsh environments. Widely adopted in industrial and consumer electronics, it ensures that devices like the best rugged windows tablet can withstand drops, vibrations, and thermal shock.

ONErugged’s products undergo a full suite of MIL-STD-810 tests. Whether you are deploying a rugged linux laptop for field operations or a standard Windows device, our hardware earns certifications that validate reliability in extreme conditions.

Depending on the model, ONErugged devices are certified under MIL-STD-810G or the updated MIL-STD-810H standards. While MIL-STD-810H introduces refinements, the core testing parameters ensure that our military tablet solutions deliver consistent, high-level durability.

Drop testing is a cornerstone of MIL-STD-810 certification, simulating accidental falls that devices may encounter in the field. ONErugged’s drop reliability testing is exceptionally thorough. Each device undergoes 26 drops—covering all six faces, eight corners, and twelve edges—to ensure comprehensive impact resistance.

The directed free-fall drop test evaluates a device’s ability to withstand impacts from a specified height. Most ONErugged products are tested at a 1.22-meter drop height onto a plywood surface. Select models even pass 1.5-meter to 1.8-meter drop tests. This is crucial for users carrying a rugged tablet on construction sites where falls are frequent.

Standard: MIL-STD-810H w/Change 1:2022, Method 516.8

Drop Height: 122 cm

Drop Count: 26 drops (6 faces, 8 corners, 12 edges)

Result: Post-test, our devices remain fully functional, proving they are built to last.

The tumble drop test replicates continuous impacts, mimicking scenarios where an android rugged mobile pda or small tablet might tumble down stairs or slip from a vehicle. ONErugged devices undergo 100 cycles of 0.5-meter tumble drops in a rotating drum lined with steel plates.

Equipment: Tumble Drop Chamber

Drop Height: 50 cm (8 inches and above), 100 cm (smaller handhelds)

Cycle: 100 cycles (simulating 200 drops)

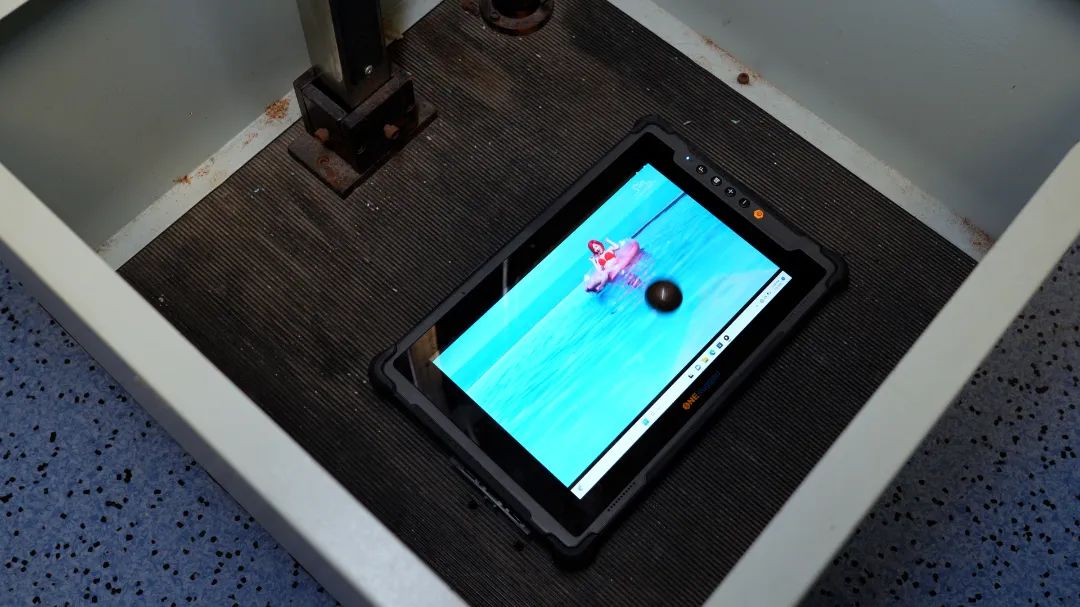

To validate the durability of our screens—essential for an industrial panel pc windows 10 used in heavy industry—ONErugged conducts steel ball impact tests. A 64-gram steel ball is dropped from 110 cm onto the screen’s center. This ensures our Corning Gorilla Glass or Panda Glass screens maintain functionality even after significant screen stress.

Vibration testing is critical for mobile workforce hardware, particularly for any in-vehicle tablet mounted in forklifts, police cruisers, or trucks. ONErugged employs random vibration testing, which uses variable amplitudes and frequencies to closely mimic real-world road conditions.

Our devices are tested across X, Y, and Z axes for 1 hour per direction (3 hours total), with a frequency range of 5–500 Hz.

Relevance: This test proves that whether you are using a rugged linux laptop or a vehicle-mounted display, the internal components will not loosen or fail during transport.

Standard: MIL-STD-810H w/Change 1:2022, Method 514.8C-I

Vibration Directions: X, Y, Z axes

In Extreme Testing Ground: Episode 1, we’ve provided a first-hand look at our testing processes. Our state-of-the-art laboratory ensures that every device meets and exceeds MIL-STD-810 requirements. From rugged tablet news enthusiasts to enterprise procurement managers, our commitment to quality is clear.

Join us for Extreme Testing Ground: Episode 2, where we’ll test ONErugged devices in extreme temperatures. Discover how our rugged technology solutions continue to lead the industry.

A military tablet is defined by its compliance with MIL-STD-810 standards (such as 810G or 810H). This certification ensures the device can withstand harsh environmental conditions, including drops from 1.22 meters, shock, and vibration, making it suitable for tactical and industrial use.

Yes. The physical durability of our hardware is consistent regardless of the OS. Whether you require a rugged Linux tablet, an industrial panel PC with Windows 10, or an Android system, the chassis and internal protection undergo the same rigorous drop and vibration testing.

An in-vehicle tablet (mounted in forklifts or trucks) experiences constant, unpredictable vibrations rather than a steady shake. Random vibration testing simulates these real-road conditions to ensure the device's mounting points and internal components don't fail during transit.

ONErugged offers top-tier contenders for the title of best rugged Windows tablet. Our devices combine high-brightness screens (readable in sunlight) with the impact resistance detailed in this article, making them ideal for outdoor field services.