The "Data Black Hole" on the Production Line

It was 3 am, and the new-energy vehicle assembly workshop was ablaze with light. The quality control supervisor stood by the assembly line, frustratedly eyeing the tablet in his hand that had just gone dark. This was the seventh time this month that the equipment had malfunctioned. The workshop's 70% humidity caused a thick layer of water mist to form on the touch screen. The intense overhead lighting created such strong glare that workers had to hunch over to find a spot where they could actually see the screen. What's more, the compatibility issues between the device's interface and the old-fashioned torque sensor meant quality inspection data was getting lost all the time. A network-delay-induced misjudgment nearly led to 300 battery packs being wrongly assembled and sent out. The quality control supervisor knew that as manufacturing precision requirements hit the 0.1-millimeter mark, traditional industrial tablets were now the weakest part of the quality control system.

M20A: "Must-Have Parameters" for Reconstructing the Industrial Data Chain

The ONERugged M20A is a rugged mobile PC that directly tackles the four main pain points in automotive manufacturing with its precise parameters and great adaptability to different work scenarios.

Computing Power Redundancy: A Container for Complex Algorithms

The M20A comes with the 12th-generation Intel® Core™ i5-1235U/i7-1255U processor. This rugged mobile PC can handle multiple tasks simultaneously in the workshop, like AI visual inspection, 3D laser welding point modeling, and data interaction with the MES system. Its 16GB DDR4L memory is so efficient that it can analyze door-gap images taken by a 5-megapixel camera in just 0.8 seconds. The 128GB removable SSD can export 2.4TB of original welding parameter data every day and supports hot-swapping for storage expansion. This stops the production line from shutting down due to data overload.

Optical Breakthrough: A Screen That Penetrates Industrial Light Pollution

When there's intense argon arc welding light, the M20A's 12.2-inch FHD screen really shines. With a resolution of 1200*1920 and a brightness of 650cd/m², it cuts through the glare. The screen is covered in 7H-hardness glass, which means it can still clearly show 0.01-mm-level body size differences even if it gets scratched by metal bits. What's really cool is that its 10-point capacitive touch works great even when workers are wearing gloves covered in cutting fluid. They can easily drag thermal imaging diagrams of welding points to compare with past data.

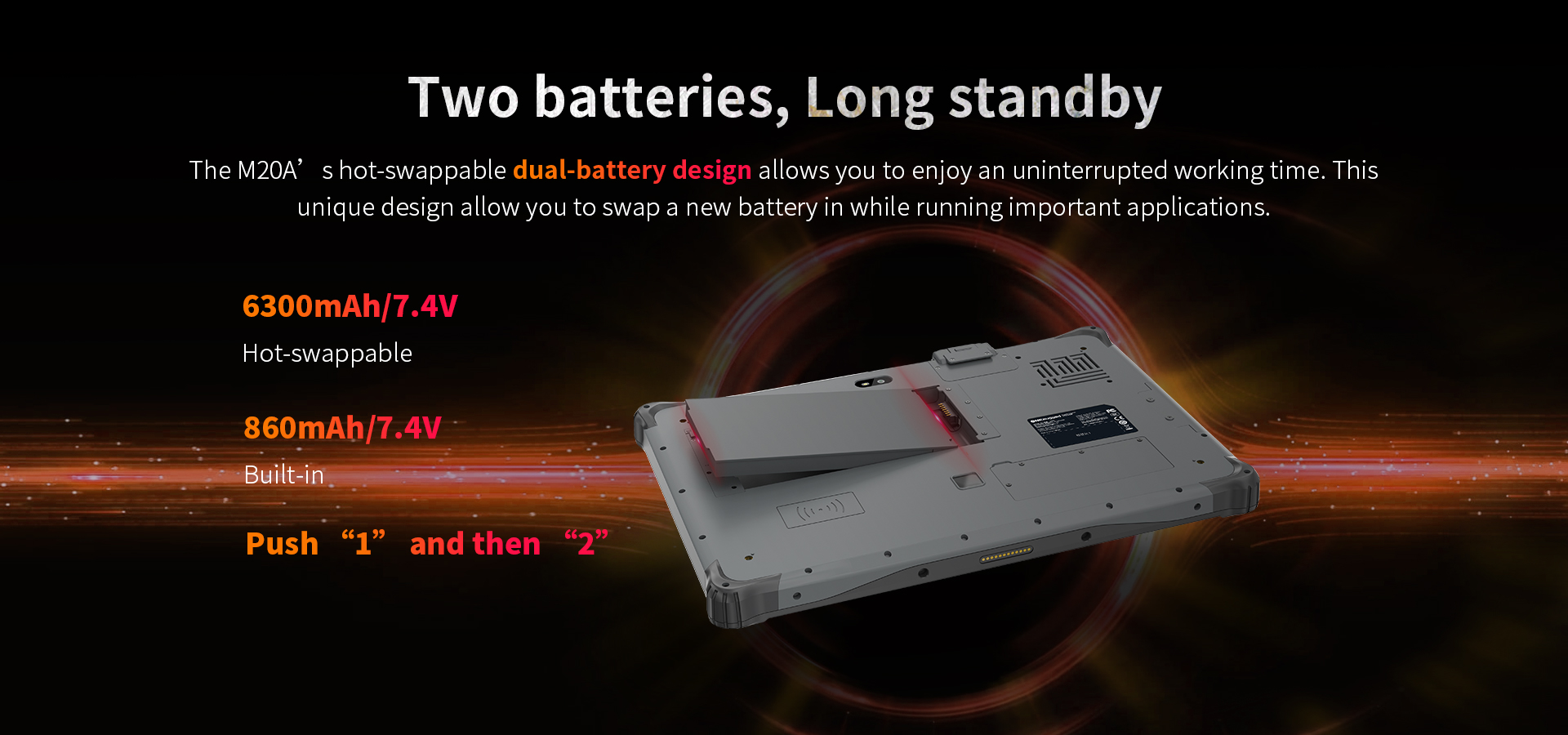

Energy Logic: A Continuous Production Line "Heartbeat"

The M20A has a dual-battery setup: 7.4V/6300mAh (hot-swappable) + 7.4V/860mAh. The big battery can be swapped out in 2 minutes, while the small one keeps the PLC control signals flowing. In a 24-hour running painting workshop, workers can change the power source without turning off the machine. This ensures that the robot spraying trajectory data is recorded continuously for over 12 hours. This "heartbeat-style" power supply gets rid of the risk of the device shutting down unexpectedly.

Interface Ecology: A Universal Socket for Industrial Equipment

On the assembly line, there are Japanese PLCs, German tightening guns, and domestic AGVs all being used together. The M20A, as a rugged mobile PC, overcomes the protocol problems with its "four-in-one module slot". You can connect a lidar detector directly to the RJ45 Gigabit Ethernet port, use the USB 2.0 port for a high-precision electronic torque wrench, read data from a 1998-made pressure sensor with the RS232 serial port, or switch to a QR-code module to scan the vehicle frame VIN code. Along with its full-function Type-C, USB3.1, and HDMI 2.1a Mini interfaces, the workshop can project real-time defect images onto 10 monitoring screens, building a comprehensive quality monitoring system.

Environmental Tolerance: The Physical Law of Data Collection

In a battery workshop where the temperature can change quickly (it can handle - 20℃ to 60℃), the M20A's IP65 protection stops electrolyte vapor from causing damage. It's built-in 6Ω/1W waterproof speaker can still sound alarms even in 85-decibel noise. With dual-band WiFi6 and 4G (or optional 5G) dual-channel network, AI quality inspection results can reach the robotic arm emergency stop system in just 50ms. Even when the roof laser welder makes the vibration reach 4.3 Grms, this rugged mobile PC still runs smoothly. It meets the tough physical demands of precision manufacturing.

Success Story: "Quantum Error Correction" in the Welding Workshop

A certain car brand started using the M20A as the main quality inspection device in its body-in-white welding line. At the sparky workstations, the M20A is connected to 32 welding gun controllers and 128 groups of infrared temperature sensors at the same time. Its 650-nit screen can show the weld pool's shape in real-time, even in strong arc light. By working with a 1989-made current monitor through the RS232 module, the accuracy of predicting welding defects has gone up to 99.7%. Thanks to the dual-battery hot-swap design, the battery can be changed without stopping the production line. Three months later, the workshop's daily production capacity went up by 40%, and the time it took to trace quality issues dropped from 45 minutes to just 7 seconds. The chief engineer said, "This isn't just upgrading the equipment; it's changing the whole way we produce."

Conclusion

The development of automotive manufacturing is all about the balance between data accuracy and environmental tolerance. The M20A, a powerful, rugged mobile PC, uses its parameters as a starting point. It turns its 12.2-inch screen into a tool to see through industrial challenges, its removable SSD into a way to manage data, and its dual-battery setup into a new way to keep the production line running smoothly. When every parameter is designed to solve industry problems, reliability becomes the key to good quality.