Summary

A leading home furnishing brand has adopted ONERugged V10J vehicle PC to build an efficient and intelligent warehouse management system. With powerful computing performance, the V10J seamlessly integrates with the warehouse management system (WMS). It connects to a Bluetooth scanner to capture goods data, and syncs in real time with the server over Wi-Fi. It also features GPS, a high-brightness screen, and versatile interfaces. These capabilities help streamline warehouse tasks like inbound/outbound handling and transport, boosting productivity and supporting the digital transformation of forklift operations.

Client Overview

The client is a modern home textile enterprise that integrates R&D, production, and sales, specializing in comforters, bedding sets, and window coverings. Its products are widely sold in both domestic and international markets. By introducing intelligent equipment and building a streamlined production system, the company witnesses a sustained improvement in product quality and operational efficiency. Through the innovative use of smart manufacturing and industrial internet technologies, it has steadily established a leading position in the industry.

Challenge

As the business expanded and market demands shifted, the client began to seek greater efficiency, accuracy, and intelligence in warehouse operations. Although rugged vehicle PCs had already been deployed, several issues emerged during daily use, limiting the optimization of warehouse management.

To start, recent upgrades to hardware and software exposed the limitations of previous devices. Their processors struggled to support the new systems, causing frequent lag and slow response times that disrupted workflow.

On top of that, poor heat dissipation led to overheating during prolonged use, resulting in system instability and occasional crashes. To mitigate the issue, external USB fans had to be added, which not only compromised both the device's usability and appearance but also introduced new risks, such as unstable power supply and cable interference.

To overcome these obstacles, the client urgently needed a lighter, faster, and smarter terminal solution to enable a full-scale upgrade and digital transformation of its warehouse system.

Workflow

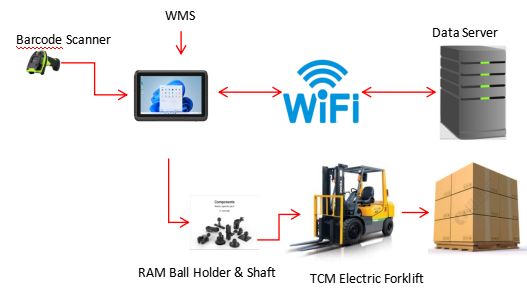

The client has built an efficient and intelligent warehouse management solution by introducing ONERugged V10J vehicle PC. Compared to the previous devices, the V10J features the Intel® Jasper Lake N5100 processor, addressing issues such as inconvenient operation, system lag, and poor heat dissipation, while enhancing operational efficiency and system stability.

Mounted securely inside the cabin of a TCM electric forklift via ball holders and shafts, the V10J supports flexible multi-angle adjustments, allowing operators to optimize viewing angles and ease of use.

During inbound and outbound flows, the V10J connects to the back-end system in real time via Wi-Fi, ensuring timely task dispatch and accurate data synchronization. Forklift operators can log into the WMS to receive task instructions and access information on inventory and cargo status. The 10.1-inch high-definition and high-brightness screen ensures that cargo codes, quantities, and storage locations are clearly displayed even under strong lighting.

During operations, the built-in GPS feature assists with tracking the forklift's location, while the warehouse system intelligently plans the most efficient route. The device connects to a Bluetooth barcode scanner for quick and accurate data collection and automatically syncs with the system, which improves the efficiency of finding items and entering information. Operators then follow system instructions to efficiently complete tasks such as picking, transporting, and loading goods.

At the end of the process, operators can submit task status directly via the device. Task results are uploaded to the server in real-time via Wi-Fi, forming a closed-loop workflow from task reception to execution and feedback. The system supports full-process monitoring, enabling managers to track operations in real time and make informed decisions based on accurate data.

The V10J’s built-in dual-band Wi-Fi ensures stable and reliable data transmission across the warehouse under a fully covered wireless network. This dramatically improves operational efficiency, as operators can receive tasks, access information, and provide feedback in real time without unnecessary movement. In addition, Bluetooth connectivity enables seamless integration with barcode scanners for real-time cargo identification and inventory updates, minimizing manual input errors and ensuring accurate data transmission.

Powered by Intel® Jasper Lake™N5100 processor and Windows 11, the V10J seamlessly connects to the existing WMS. With real-time forklift positioning via GPS and integrated location data, the vehicle PC can guide operators to target zones. From inbound and outbound logistics to handling and loading, the system enables closed-loop task management and facilitates automation and overall operational efficiency.

The V10J is certified to IP65 standards and capable of stable operation in temperatures from -20°C to 60°C. It supports both VESA and RAM mount installations, allowing for easy setup and removal. Having passed extreme vibration tests, the V10J ensures operational stability and clear screen visibility even under constant vibration and jolting, delivering reliable performance for intensive warehouse operations.

The V10J features a large-area plate-fin heat sink that rapidly dissipates heat under heavy workloads, ensuring stable and smooth performance without lag over long periods. It supports 9V to 36V wide-voltage input and is compatible with various power sources, including cigarette lighter adapters and aviation power connectors, enabling continuous operation in dynamic warehouse environments.